Furnace Heaters

Tubothal Heaters/Bundle Heater

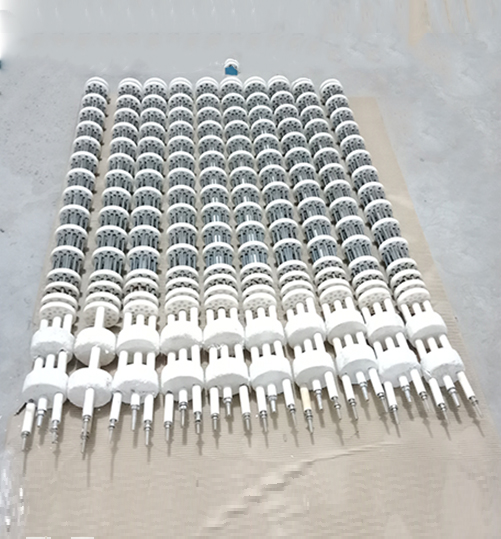

Tubothal/Bundle heater consists of circular ceramic beads that hold the heating elements. Also known as Bayonets, they are designed for long life and maintenance free operation. The elements can be provided in almost any length but the standard dimensions available are 32 to 200 mm (1.25 to 8 inch). These heaters can be used as standalone elements or inside radiant tubes. Because of the ingenious design, Bundle rod heating elements deliver a much higher power than conventional cartridge heaters. In combination with radiant tubes, a system is created which delivers high power, is rugged, versatile and needs low maintenance. Designed & manufactured in low voltages for faster heating in order to achieve temperatures quickly, these heaters can be mounted horizontally or vertically. Either NiCr alloy or FeCrAl alloy can be used as heating element. For temperatures up to 2100°F (1150°C), Austenitic (NiCr) alloy (80/20 or 70/30) and for temperatures up to 2597°F (1425°C), FeCrAl alloy can be used.

Easy installation

Due to its ruggedness and versatility, bundle rod elements are easy to install and replace. Compatibility with radiant tubes allows installation to be either horizontal or vertical depending on the application. Easy repair and high temperature performance gives it an edge over others. Custom designed for the voltage and wattage required, bundle rod heaters are used in heat treat furnaces and die casting machines to molten salt baths and incinerators. With radiant tubes they can be used in high velocity convection furnaces and sealed quenched furnaces. They are also useful in converting gas-fired furnaces to electric heating.

Superior Power Output

Tubothal/Bundle rod elements, with a higher power output, leads to major saving in cost and maintenance. Also when combined with radiant tubes, they give highest power rating (up to 400 kW) as compared to any other heater.

Options: | |

| Heating Element Material | Wattage |

| NiCr / FeCrAl alloy | 3 kW / 400 kW |

| Max. Temperature | 1200 ° C / 1425 ° C |

| Diameter | 32 to 200 mm |

| Length | As Per Requirement |

| Voltage | 24V – 480 V AC |

Silicon Carbide Heating

The silicon carbide heating element. Starbars are rod shaped or tubular depending on the diameter. They have a central heating section referred to as a hot zone and two terminal sections called cold ends. There are two types of RR Starbars. (1) The cold ends are impregnated with silicon metal – referred to as one piece, and (2) low resistance cold ends which are furnace welded to the hot zone – referred to as a three piece or LRE (Low Resistance End) type. This lower electrical resistance cold end causes them to operate at a lower temperature. The extremities of the elements are metallized with aluminum to provide a low resistance contact surface to which the electrical connections are made using braided aluminum straps.

RR Starbars are described by giving the overall length, the heating section length, and the diameter.As an example, RR 43×24×1 is a Starbar 43” overall with a 24” hot zone, and 1” in diameter.

Item | Diameter | Maximum Overall Length | Hot Zone (Electrical Resistance) | Cold End (Electrical Resistance) |

| RR-3/8-10 | 3/8 Inch | 26 Inch | 0.3486 Ohms/Inch | 0.01743 Ohms/Inch |

| 10 mm | 660 mm | 0.01372 Ohms/mm | 0.000686 Ohms/mm | |

| R-7/16-11 | 7/16 Inch | 36 Inch | 0.2563 Ohms/Inch | 0.01282 Ohms/Inch |

| 11 mm | 915 mm | 0.01009 Ohms/mm | 0.000505 Ohms/mm | |

| RR-1/2-13 | 1/2 Inch | 42 Inch | 0.1963 Ohms/Inch | 0.00982 Ohms/Inch |

| 13 mm | 1090 mm | 0.00773 Ohms/mm | 0.000387 Ohms/mm | |

| RR-5/8-16 | 5/8 Inch | 50 Inch | 0.1262 Ohms/Inch | 0.00631 Ohms/Inch |

| 16 mm | 1250 mm | 0.00497 Ohms/mm | 0.000248 Ohms/mm | |

| RR-3/4-19 | 3/4 Inch | 62 Inch | 0.0865 Ohms/Inch | 0.00433 Ohms/Inch |

| 19 mm | 1575 mm | 0.00341 Ohms/mm | 0.00017 Ohms/mm | |

| RR-1-25 | 1/1 Inch | 74 Inch | 0.05 Ohms/Inch | 0.0025 Ohms/Inch |

| 25 mm | 1900 mm | 0.00197 Ohms/mm | 0.000098 Ohms/mm | |

| RR-1-1/4-32 | 1-1/4 Inch | 86 Inch | 0.0343 Ohms/Inch | 0.00171 Ohms/Inch |

| 32 mm | 2210 mm | 0.00134 Ohms/mm | 0.000067 Ohms/mm | |

| RR-1-3/8-35 | 1-3/8 Inch | 90 Inch | 0.027 Ohms/Inch | 0.00135 Ohms/Inch |

| 35 mm | 2290 mm | 0.00106 Ohms/mm | 0.000053 Ohms/mm | |

| RR-1-1/2-38 | 1-1/2 Inch | 92 Inch | 0.0234 Ohms/Inch | 0.00117 Ohms/Inch |

| 38 mm | 2340 mm | 0.00092 Ohms/mm | 0.000046 Ohms/mm | |

| RR-1-3/4-45 | 1-3/4 Inch | 104 Inch | 0.020% Ohms/Inch | 0.00082 Ohms/Inch |

| 45 mm | 2670 mm | 0.00065 Ohms/mm | 0.000032 Ohms/mm | |

| RR-2-1/8-54 | 2-1/8 Inch | 130 Inch | 0.015 Ohms/Inch | 0.00075 Ohms/Inch |

| 54 mm | 3300 mm | 0.00059 Ohms/mm | 0.00003 Ohms/mm | |

| RR-2-3/4-70 | 2-3/4 Inch | 130 Inch | .007298 Ohms/Inch | .00052 Ohms/Inch |

| 70 mm | 3300 mm |