High Density Cartridge Heaters

High Density Cartridge Heaters

Hi-Density Cartridge Heaters Provide Maximum Processing Temperature Capability.Multi-purpose Cartridge Heaters are the Solution to OEM or Maintenance Applications

Features- The standard termination for Hi-Density Cartridge Heaters is Type N, 254 mm (10″) long nickel conductor lead wires externally connected to 32 mm (11⁄4″) solid conductor terminal pins. The lead wires have fiberglass insulation and are UL approved for temperatures up to 250°C (482°F). Mica insulated UL approved wires for temperatures up to 450°C (842°F) are optional

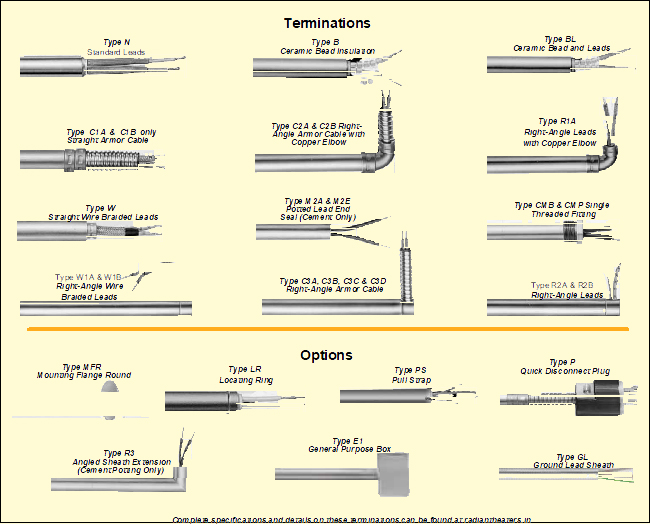

- Note: To meet the requirements of your application we offerover 40 standard termination styles to select from that will solve many of the most common application problems. Consult Omega for available options.

- Ceramic end cap prevents nickel conductors from shorting out against sheath when sharp bending of the leads is required. The ceramic cap may be eliminated in some cases to optimize the heater watt density.

- Ceramic end cap and swaged-in lava plug protect the internal cartridge from outer contamination. Other types of seals can also be provided.

- Solid conductor terminal pins are used to ensure a good electrical connection between the nickel conductor lead wires and the resistance wire. They are sized for the maximum current rating of the heater

- Specially selected grain size high purity Magnesium Oxide (MgO) is used to fill all remaining space inside the sheath. Heater is then swaged, which compacts the magnesium oxide grains into a solid mass, thereby increasing thermal conductivity and dielectric strength.

- Standard sheath material is 321 Stainless Steel. It provides high temperature strength up to 650°C (1200°F), good thermal conductivity, and resistance to corrosion and scaling. Alloy 321 is a Nickel-Chromium Stainless Steel modified with the addition of Titanium. For higher operating temperatures up to 760°C (1400°F) or corrosive immersion heating applications, Incoloy® 800 is available. Consult Paramount for other sheath materials.

- Grade “A” Nickel-Chrome resistance wire precisely wound on a high purity magnesium oxide core places the resistance wire as close to the inside of the sheath as possible while maintaining dielectric strength. This provides excellent heat transfer and long heater life with the highest possible watt densities. Welded end disc made from the same material as the sheath provides a positive seal against moisture and other contaminants.

- * Hi-Density Cartridge Heaters are UL recognized and CSA certified in manydesign variations under UL File Number E65652 and CSA File Number043099. If you require UL and/or CSA Agency Approval, please specify when ordering.

Tubothal Heaters/Bundle Heater

Tubothal/Bundle heater consists of circular ceramic beads that hold the heating elements. Also known as Bayonets, they are designed for long life and maintenance free operation. The elements can be provided in almost any length but the standard dimensions available are 32 to 200 mm (1.25 to 8 inch). These heaters can be used as standalone elements or inside radiant tubes. Because of the ingenious design, Bundle rod heating elements deliver a much higher power than conventional cartridge heaters. In combination with radiant tubes, a system is created which delivers high power, is rugged, versatile and needs low maintenance. Designed & manufactured in low voltages for faster heating in order to achieve temperatures quickly, these heaters can be mounted horizontally or vertically. Either NiCr alloy or FeCrAl alloy can be used as heating element. For temperatures up to 2100°F (1150°C), Austenitic (NiCr) alloy (80/20 or 70/30) and for temperatures up to 2597°F (1425°C), FeCrAl alloy can be used.

Dimensional Specifications

| Nominal Diameter | 1⁄8″ | 1⁄4″ | 5⁄16″ | 3⁄8″ | 1⁄2″ | 5⁄8″ | 3⁄4″ | 1″ |

| Actual Diameter mm (inch) | 3.10 (0.122) | 6.25 (0.246) | 7.82 (0.308) | 9.42 (0.371) | 12.60 (0.496) | 15.77 (0.621) | 18.95 (0.746) | 23.30 (0.996) |

| Diameter Tolerance | 0.051 (±0.002) | 0.051 (±0.002) | 0.051 (±0.002) | 0.051 (±0.002) | 0.051 (±0.002) | 0.051 (±0.002) | 0.076 (±0.003) | 0.076 (±0.003) |

| Minimum Length | 31.8 (1.25) | 25.40 (1) | 25.40 (1) | 25.40 (1) | 25.40 (1) | 25.40 (1) | 31.75 (11⁄4) | 44.45 (13⁄4) |

| Maximum Length | 305 (12) | 914 (36) | 914 (36) | 1219 (48) | 1219 (48) | 1829 (72) | 1829 (72) | 1829 (72) |

| Length Tolerance Heaters over 127 mm (5″) long | ||||||||

| ±2% of sheath length | ||||||||

| Camber Tolerance Heaters to 305 mm (12″) long | ||||||||

| 0.254 mm (0.010″) per foot of length | ||||||||

| Camber Tolerance Heaters over 305 mm (12″) long | ||||||||

| 0.508 mm (0.020″) per foot of length | ||||||||

A certain amount of camber is unavoidable. With a slight force, hi-density cartridge heaters will flex enough to fit into a straight reamed hole.

Electrical Specifications

| Nominal Diameter | 1⁄8″ | 1⁄4″ | 5⁄16″ | 3⁄8″ | 1⁄2″ | 5⁄8″ | 3⁄4″ | 1″ |

| Maximum Voltage | 240 | 240 | 240 | 240 | 240 | 480* | 480* | 480* |

| Maximum Amperage | 3 | 4.4 | 4.5 | 6.7 | 10.5 | 23 | 23 | 23 |

| (see next line for exceptions) | ||||||||

| †Maximum Amperage for Types | — | 3 | 3 | 5.5 | 7.6 | 9.7 | 9.7 | 9.7 |

| C1C, C1D, C2C, C2D, CS, F, M3, R1B, | ||||||||

| S1, S2, SA, W andW3 Terminations | ||||||||

| Minimum Wattage at 120V on a 1″ long Heater | — | 50 | 45 | 45 | 50 | 50 | — | — |

| Minimum Wattage at 120V on a 2″ long Heater | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Maximum Wattage at 120V | 360 | 525 | 540 | 800 | 1260 | 2760 | 2760 | 2760 |

| Maximum Wattage at 240V | 720 | 1050 | 1080 | 1600 | 2520 | 5520 | 5520 | 5520 |

| Maximum Wattage at 480V | — | — | — | — | — | 11,000 | 11,000 | 11,000 |

| Wattage Tolerance | +10, -15% | Plus 5%, minus 10% | ||||||

| Resistance Tolerance | +15, -10% | Plus 10%, minus 5% | ||||||

Temperature Coefficient of Resistance

The electrical resistance (ohms) of the heater resistance wire increases with temperature rise. Paramount standard hi-density cartridge heaters are manufactured with ohms (cold ohms) 3.3% lower than the actual calculated ohms (hot ohms) to compensate for this increase.

| Diameter | Dual | 3-Phase | Dual | Mult. Heat Zones |

| Volts | Circuits | Max. 3 zones | ||

| 1⁄8″ | No | No | No | No |

| 1⁄4″ | No | No | No | No |

| 5⁄16″ | No | No | No | No |

| 3⁄8″ | Yes* | No | No | Yes* |

| 1⁄2″ | Yes* | Yes | Yes | Yes* |

| 5⁄8″ | Yes | Yes | Yes | Yes |

| 3⁄4″ | Yes | Yes | Yes | Yes |

| 1″ | Yes | Yes | Yes | Yes |

Modifications & Options for Hi-Density Multi-Purpose Cartridge Heaters

PARAMOUNT stocks over 1000 different semi-finished hi-density cartridge heaters in diameters 6, 8, 10, 13,16, and 19 mm (1⁄4, 5⁄16, 3⁄8, 1⁄2, 5⁄8 and 3⁄4″). These cartridge heaters are semi-finished (substrates), offering you the option to finish them by choosing from 19 program-qualified lead end terminations and options. Cartridge heaters will be ready for shipment within 1 to 3 days, depending on the termination/ option selected.

Ordering Information — Follow These Simple Steps

- Select an available 6 mm (1⁄4″) through 19 mm (3⁄4″) hi-density cartridge heater. The model numbers in the product data tables are for heaters with termination type N [254 mm (10″) long externally connected lead wires].

- Refer to the lead termination reference photos below to select the cartridge heater termination type best suited for your application.

- NOTE: Type “N” [254 mm (10”) long externally connected plain lead wires] is the most common termination. If a termination other than Type N is selected a new permanent part number will be assigned when your order is placed.

- Specify your lead requirements in the event that the standard supplied lengths for plain leads 254 mm (10″), braid or armor cable [254 mm (10″) over 305 mm (12”) leads] are not suited for your application.

- Specify the quantity.